Microscopic tests

Observation of the microstructure is an elementary test that allows to determine the correctness of the metallurgical operations performed in accordance with the requirements of international standards and customers.

An experienced metallographer is able to predict the properties of the tested material on the basis of the observed microstructure. Microscopic examinations are performed for both metals and plastics.

We make:

identification of microstructure and material

identification of the manufacturing and processing of the material

qualitative analysis of the microstructure

evaluation of the characteristics of the particles of graphite

coating thickness measurement

evaluation of the content of non-metallic inclusions

evaluation of grain size

quantitative analysis of the share of phases, defects, porosity

determining the size of defects, e.g. delamination, corrosion depth

determination of the depth of decarburization / carburization by metallographic method

determination of the thickness of surface hardened layers using the metallographic method

Accredited research

qualitative analysis of structure components by optical microscopy

evaluation of grain size using the comparative method according to the pattern scale in accordance with PN-EN ISO 643: 2013-06

Equipment:

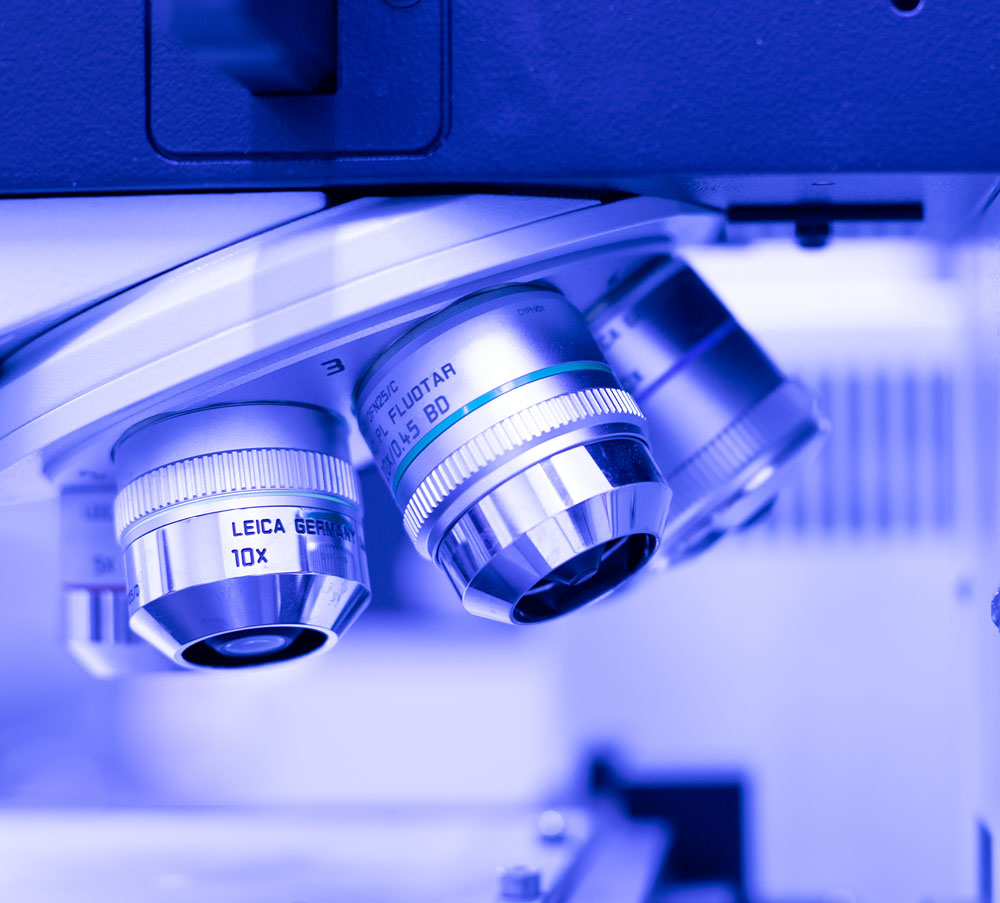

Automated metallographic microscope Leica DM6000M and Leica DM4 M

Keyence VHX 6000 digital microscope

Phenom World ProX scanning microscope with EDS / EDX microanalyzer of chemical composition

Phenom XL scanning microscope with EDS / EDX chemical composition microanalyzer

Leica DM500 metallographic microscope

Scanning microscope

We use a scanning electron microscope to observe the surface and microstructure of samples at high magnifications and the required depth of field. The dimensions of the samples are limited by the size of the microscope chamber and the dimensions of the stage.

The laboratory has software that allows for:

three-dimensional reconstruction of microstructures and surfaces

automatic evaluation of grain size

automatic evaluation of graphite particles

performing a statistical analysis of the share of individual phases of the microstructure (quantitative metallography)

roughness measurement by optical method

testing the cleanliness of components and parts (contamination on filters / filters)

Preparation

In order to make correct metallographic observations with the use of light and electron microscopy methods, it is necessary to prepare a good-quality metallographic sample. Many years of experience of the staff in the field of metallography guarantees professionalism and correctness of microscopic examinations.

Equipment:

automatic hot mounting press Leco PR4

automatic grinding-polisher Leco GPX200 with a slurry feeder

automatic cutter for large sections Leco MSX250A

automatic precision cutter Metcon Micracut 201

Metallkraft BMBS 360 × 500 HA-DG frame band saw with a maximum cutting length of 500 mm

Vacuum Sputtering Machine Leica EM ACE200

Microscopic examinations are performed for both metals and plastic composites.

Microscopic examinations

Predicted – designed properties of metals and alloys, as well as e.g. corrosion resistance, weldability – are selected properties that can be determined on the basis of microstructure using this rapid and specific analysis method that does not require large samples. Microscopic metallographic examinations provide insight into extremely important information about the structure and microstructure of metals and alloys. The results obtained in this way can be an element of quality control, checking the impact of technological processes on the metal, and predicting its behaviour under the influence of various operating conditions. The reliability of the results, which our laboratory can provide, is crucial. Check how we work and see that it is worth trusting us!

What is the purpose of metallographic microscopic examination?

This is a specific method of analysing the structure and microstructure of metals such as steel, based on direct observation of its internal structure with light or electron microscopes. Metallographic microscopic examinations allow for the assessment of the microstructure of materials, i.e. viewing and thoroughly understanding the internal structure. Thus, it becomes possible to identify various phases, grains, discontinuities or inclusions, as well as determine their arrangement or shape. Our analyses support quality control, understanding metallurgical processes in material technology as well as destruction, corrosion and other processes.

READ MORE

Microscopic metallographic tests are carried out by specialists – they help to understand the properties and behaviour of metals in various conditions. Based on the results obtained, it is also possible to assess the quality of manufacturing or heat treatment processes. This is important because they directly translate into production efficiency and the quality of manufactured products, e.g. those made of steel.

Recommendations for performing microscopic metallographic examinations

Analytical activities are carried out when there is a need to obtain reliable information about the structure of a given material. They can be commissioned by manufacturers and metal processing companies, scientific institutions or research entities. The use of metallographic microscopic examinations is extremely wide – from product quality control, through science, to analysis of corrosion progress and material wear.

The value of our services is the ability to obtain precise information about the structure of metal. Such knowledge provides the basis for further analyses and decisions within various technological processes. Microscopic metallographic examinations help to understand what determines the properties of materials, what are the mechanisms responsible for their behaviour and what changes may occur as a result of specific activities or interactions such as heat or mechanical treatment.

Metallographic microscopic examinations carried out by our specialists are an important element of the metallurgical industry. They enable precise understanding of the properties of metals such as steel, which allows predicting their behaviour in various environments and operating conditions. The precision and reliability of the results that our company can provide are the result of the experience, knowledge and competence of the specialists who make up our team. At Machinefish, we are proud of our professionalism and commitment, which translates into the quality of the services we offer.

Step-by-step microscopic metallographic examination

When exploring the topic of metallographic and microscopic analyses, it is worth noting that they are complicated and require the highest precision and methodical approach. The first stage of the test is the appropriate preparation of a metal sample, e.g. steel, which is subjected to mechanical processing, usually consisting of grinding and polishing. The aim of these activities is to prepare the sample for observation in such a way that the observation is carried out in the right place, not at random, that the sample is not destroyed during preparation, and that the preparation reveals those microstructure features that are necessary for its proper interpretation.

The etching of microsections plays an important role in the preparation of metallographic samples. Special substances used for this purpose affect the metal surface. If the sample has been properly prepared, at this stage details of the structure will be revealed that were previously invisible. Then, using appropriate metallographic microscopy techniques, we perform detailed examination of the material. Typically, the examination is performed using optical microscopes, but depending on the needs, electron, confocal or atomic force microscopes may also be used.

Reliable and credible metallographic tests

Satisfied clients are the best proof of the quality of our services. As Machinefish Materials & Technologies, we offer comprehensive services in the field of metallographic microscopic examination. Regardless of whether it is quality control, identification of the causes of damage or failure, selection of production parameters, or surface analysis – our experienced team of specialists guarantees the accuracy and the correct interpretation of the results.

Using the latest technologies and equipment, we are able to provide a lot of detailed information about metals and alloys. Our offer includes metallographic laboratory tests in the following areas:

- chemical composition,

- microscopic examinations,

- macro- and microstructure analyses,

- hardness,

- surface morphology,

- characteristics of fractures.

We realise that precise and reliable microscopic metallographic examinations may be of key importance for many industries, which is why we focus on quality and professionalism. Remember, however, that the foundation of success is both modern technologies and the experience and knowledge of specialists that you can count on and who cooperate with our laboratory. Call or write us to order microscopic metallographic tests of metals!