Spectral analysis and microanalysis of the chemical composition

Spectral analysis of chemical composition with an optical spectrometer with glow discharge allows for a quantitative analysis of the elemental composition of metal alloys. The accuracy of analysis allows the determination of the type of test material with respect to the relevant standards.

EDS/EDX microanalysis is a method used mainly for making local analyses of chemical composition when the area to be analysed is very small (even several micrometres) or the analysed substance is, for example, a precipitate.

We make:

test of chemical composition of iron alloys (steels, cast steels, cast irons)

test of chemical composition of aluminium alloys

tests of chemical composition of copper alloys

tests of chemical composition of titanium alloys

ests of chemical composition of titanium alloys

microanalysis of impurities, corrosion products, fine particles from chemical processes and phases present in metal alloys (surface, point, linear microanalysis)

Accredited research

analysis of the chemical composition of steel, cast steels and cast irons by the method of atomic emission spectrometry with glow excitation in the ranges of the content of individual elements included in the scope of accreditation

Equipment:

chemical composition analyzer with glow discharge Leco GDS900A

chemical composition analyzer with glow discharge Leco GDS500A

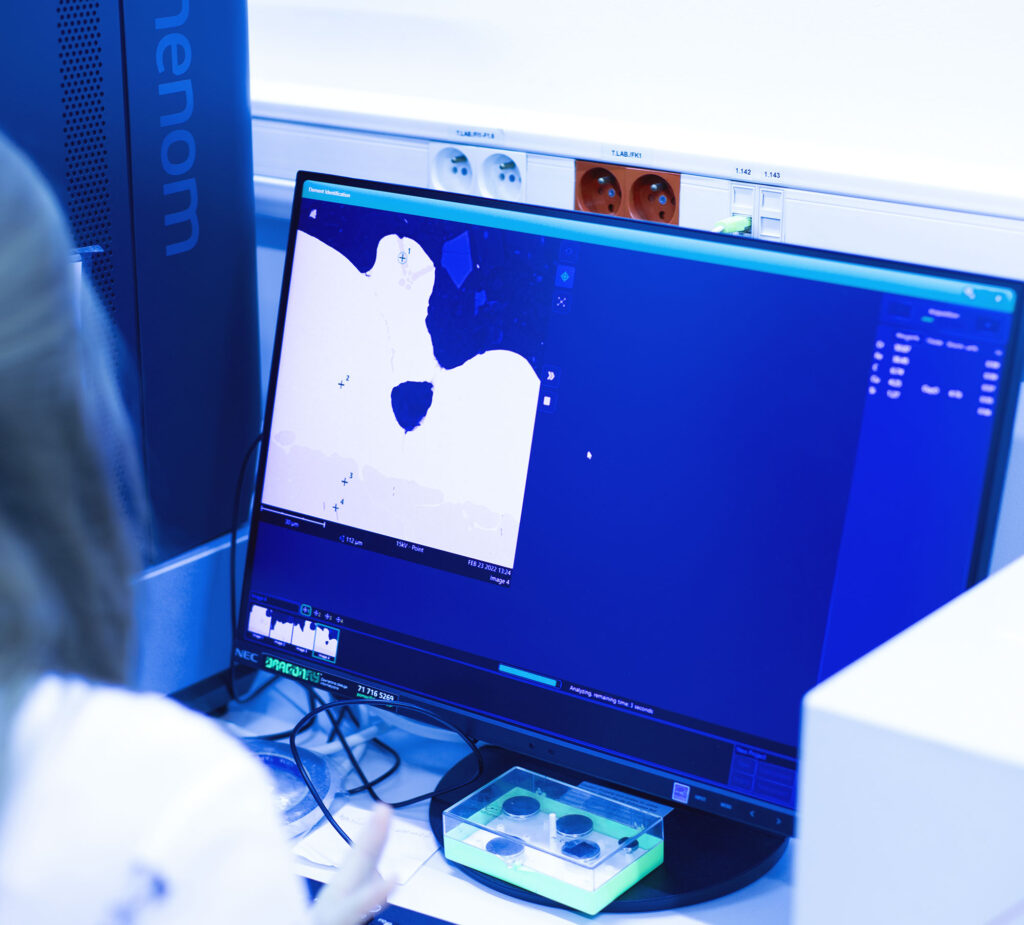

Phenom World ProX scanning microscope with EDS / EDX microanalyzer of chemical composition

Phenom XL scanning microscope with EDS / EDX chemical composition microanalyzer

Spectral analysis and microanalysis of chemical composition

The structure of materials used in broadly understood industry has a decisive impact on the properties and applications of manufactured products. Knowledge of the chemical composition is necessary to ensure the required quality and compliance with standards of various types of materials and products. Our task is to perform analyses and tests of the chemical composition of metal alloys, including steel, iron alloys, aluminium, copper, titanium and nickel. We also analyse substances and impurities that may cause failure and corrosion of machine and installation components.

We offer comprehensive and professional services tailored to the individual needs of clients from many sectors of the economy. Accreditation by the Polish Centre for Accreditation confirms that we provide services in accordance with the most up-to-date standards, and the results we obtain are credible and reliable.

READ MORE

What are chemical composition analyses and tests?

The analyses and chemical composition tests carried out by our company allow us to understand and describe the physical and chemical properties of metallic materials and the impact of various substances on their operation. The obtained results make it possible to determine the behaviour of e.g. metal alloys in various conditions, e.g. corrosion. This knowledge plays a fundamental role in the industry because it facilitates the precise selection of materials appropriate for the purpose of the machine or installation, e.g. structural steel, corrosion-resistant steel, heat-resistant steel or other.

Methods of chemical composition analysis

What methods does our laboratory use to obtain credible, reliable and valid results?

Spectral analysis of chemical composition using an optical spectrometer with glow discharge

This is an advanced technique that examines the spectrum of light emitted or absorbed by a sample. When using an optical glow discharge spectrometer, the sample is subjected to an electrical discharge in the presence of argon, which causes the formation of plasma. Excited atoms emit radiation with an intensity and wavelength characteristic of the quantitative and qualitative elemental composition of the material. The resulting spectrum is then split on a diffraction grating and chemically analysed using a CCD matrix.

Such testing allows for the identification and classification of the various elements present in the sample. This method is used in many fields of science and industry, such as chemistry, metallurgy and materials science. Our laboratory uses it for instance to identify what metallic alloy, steel or other metals we are dealing with. We analyse the chemical composition because it is one of the basic criteria characterising metal alloys.

Spectral testing using an optical spectrometer with a glow discharge provides high precision of results and can cover various metal alloys. It is also recommended due to the speed and efficiency of the analysis process. It is an essential tool for scientists and engineers involved in materials science. However, this method cannot be used to analyse non-metallic substances for which we can use the EDS/EDX method.

EDS microanalysis

EDS (Energy-Dispersive X-ray Spectroscopy) microanalysis, also called EDX (Energy-Dispersive X-ray Analysis) or EDXMA (Energy-Dispersive X-ray Microanalysis) is a technique used for elemental analysis and chemical testing of samples of substances and materials, e.g. steel and other metal alloys. This method is used to identify the elements present in a given object.

EDS is an essential tool used in materials sciences, metallurgy and geology that provides fast and precise results. This technology of testing and analysing the chemical composition of various materials and substances is characterised by high efficiency, and the results obtained thanks to it contribute to the optimisation of industrial processes.

What materials do we analyse?

Our services cover a wide variety of substances, materials, metals and their alloys, such as iron, aluminium, copper, titanium, nickel, steel and other metals that play a fundamental role in industry. We perform analyses in a professional and objective manner – all stages of chemical composition testing are carried out in accordance with applicable standards and in accordance with client’s requirements. We have advanced equipment, specialised knowledge and extensive experience, which guarantees the high quality of the services provided and the reliability of the presented analysis results.

Why and when are tests of the chemical composition of metals ordered?

Companies producing metals and their alloys, e.g. steel, commission tests to ensure that their products meet specific quality standards and applicable industrial standards. Analysis of the chemical composition allows for precise determination of the content of individual elements in a material or substance. Therefore, it becomes essential for certification and compliance with legal regulations.

The results we provide make it easier to understand how various elements and their interactions influence the properties, e.g. mechanical or thermal, of substances and materials, including metals such as steel. We are also commissioned to conduct tests by regulatory institutions and environmental organisations in order to monitor and control pollution in a given area and its impact, e.g. on the corrosion of devices and installations. Analysis of the chemical composition can detect the presence of toxic compounds that potentially negatively affect human health and the environment but also cause or accelerate corrosion of metal elements.

Reliable tests in a professional laboratory

Using the latest technologies and extensive experience, we are able to meet the individual needs and requirements of clients who want to commission testing and analysis of the chemical composition of alloys and substances or materials, e.g. steel or other metals. Use our services regardless of the purpose for which the provided results will be used!