Cause of leakage in heat exchangers

In the case of heat exchangers, the most common failure is the occurrence of leaks, refrigerant leaks. In such a situation, it is necessary to carefully look at the problem and determine the cause.

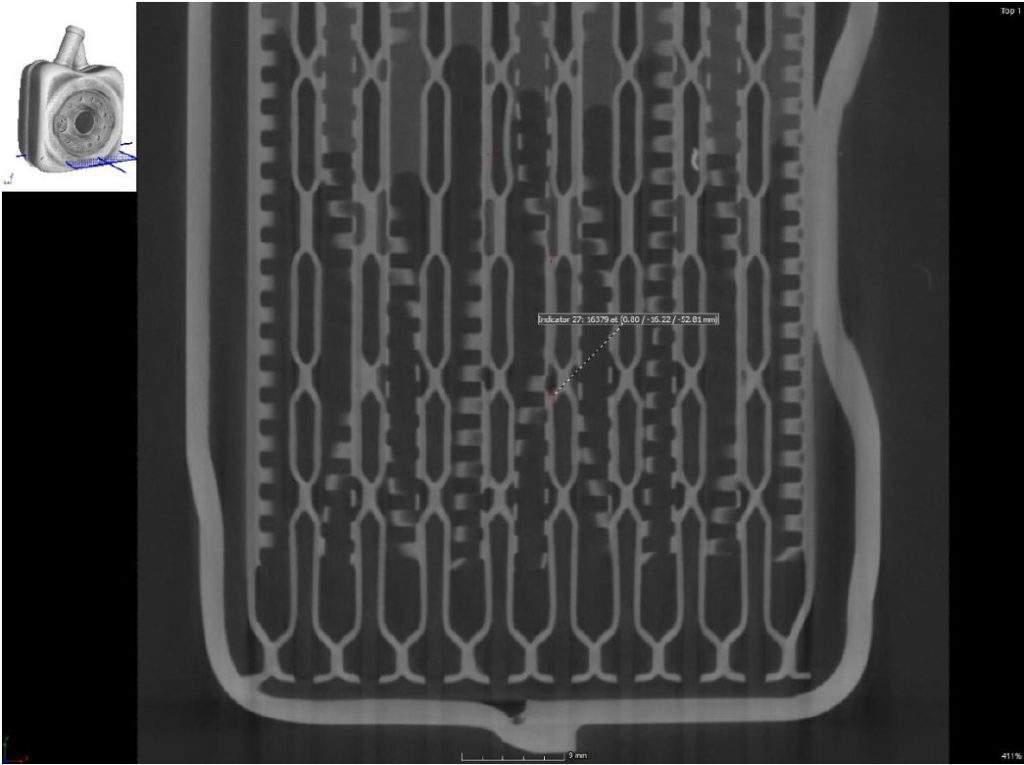

One method of identifying a leak is to perform a tomographic survey. By using this non-destructive method, the exact location of the leak and its dimensions can be easily determined.

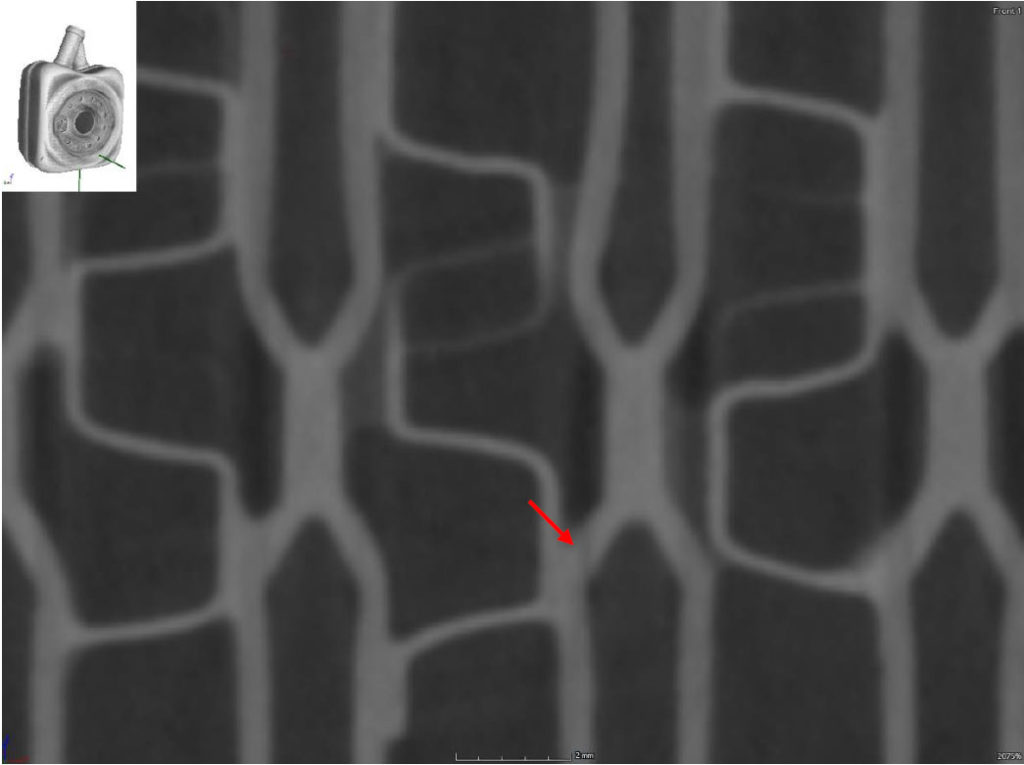

Indicated leakage (rupture) of heat exchanger on tomographic image.

Tomographic image - cross-section of a heat exchanger with the indicated leak location

Once the location of the defect has been determined, destructive testing such as microscopic examination, chemical composition analysis…

Destructive testing for leaks is the best way to answer the question – why did the failure occur? How can such events be prevented in the future?

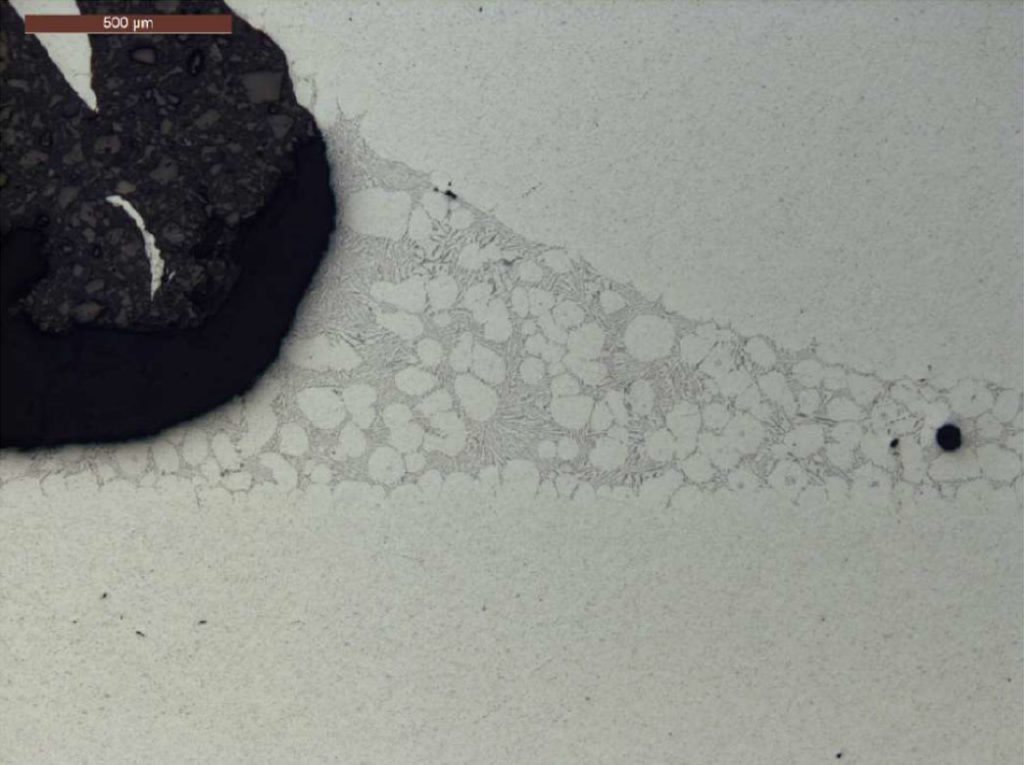

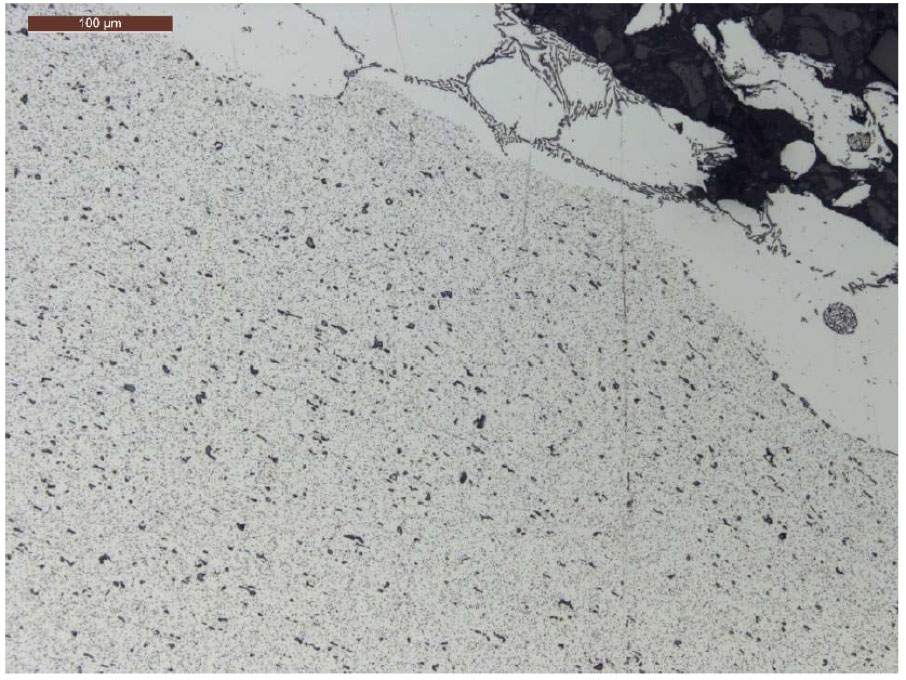

Thanks to microscopic observations we will determine the microstructure of the material and e.g. the soldered joint. In this way we will assess its quality and correctness of execution.

Microscopic image of a solder joint cross-section

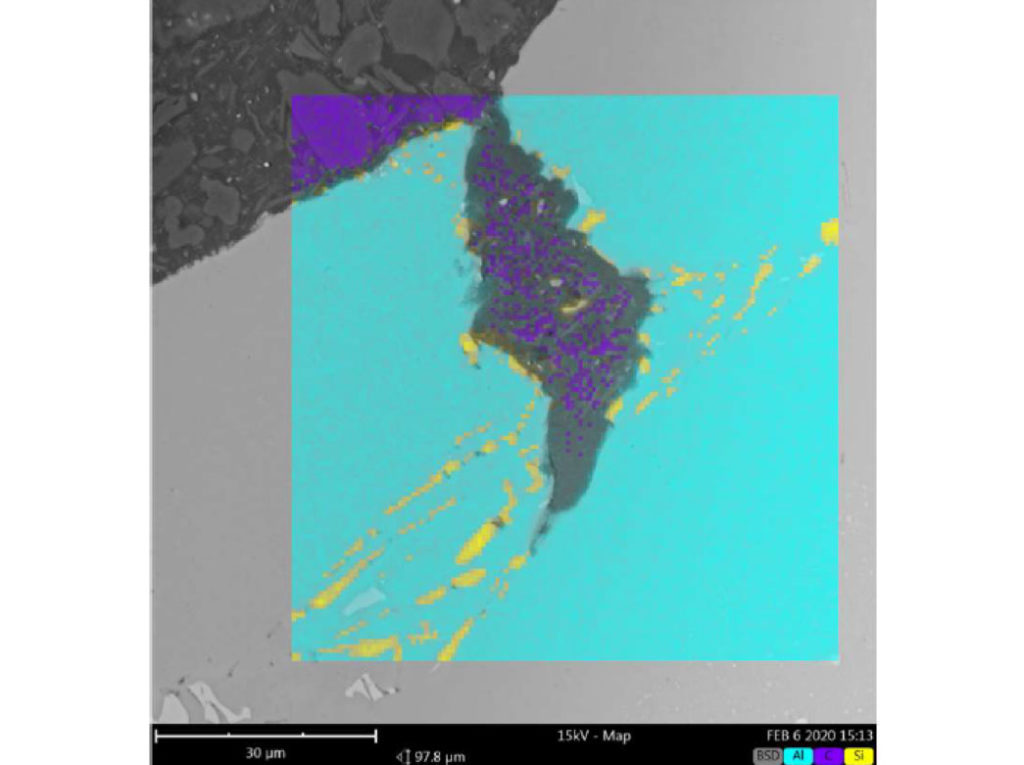

EDS/EDX microanalysis of the chemical composition showing the distribution of elements in the analyzed area at the solder joint

Microanalyses of the chemical composition of the material are also helpful. The EDS/EDX method is extremely helpful in identifying non-metallic inclusions or impurities. Determination of the chemical composition allows to determine the origin of possible impurities such as foreign metallic particles or corrosion products.

Microscopic image of a section of damaged solder

All research results along with opinions and interpretations are made available to the Client in the form of a clear and comprehensive research report.