Micro and macroscopic examination of the interference connections of copper pins with copper sleeves

We obtained glass fiber reinforced composite plates with thin layers of copper, which are part of the electronic system.

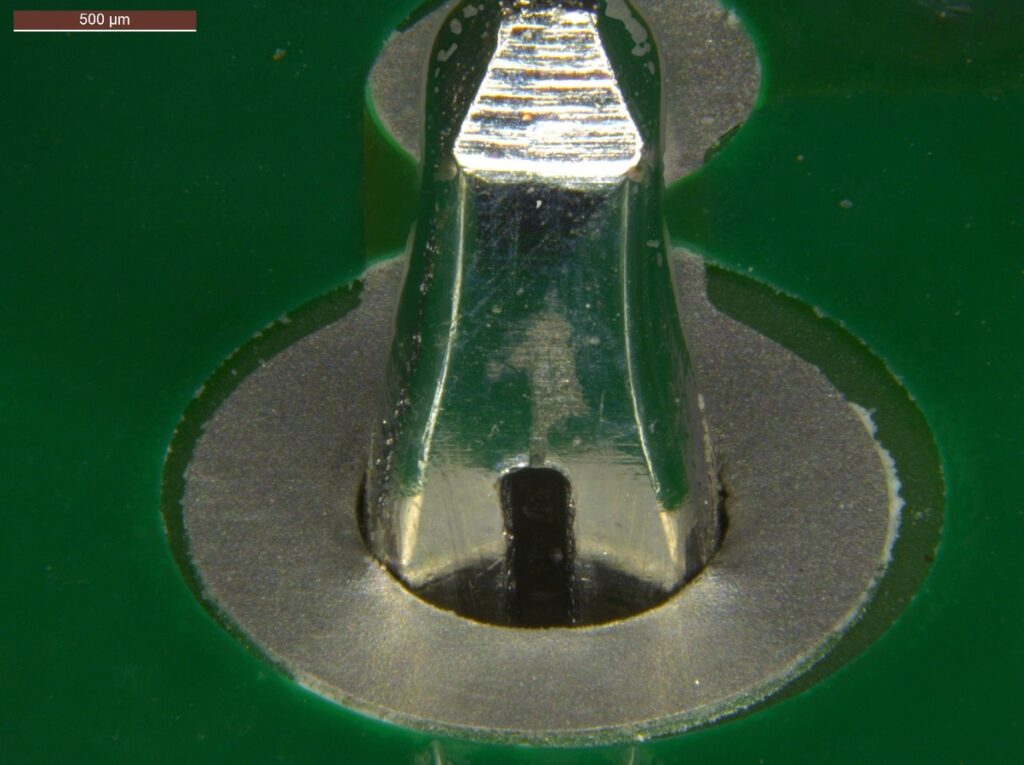

The tests were aimed at checking whether the design requirements for the push-in connection of the copper pins were met. We checked the fulfillment of the connection requirements – i.e. the continuity of the copper layer at the connection point, deformations and deviations of the press-fit elements. Contrary to appearances, the order was demanding due to the small size of the details, on which a series of destructive tests had to be performed, and each of the boards had as many as five pins. We present a top view of the pin pressed into the sleeve. It is worth paying attention to the scale!

Due to the aforementioned design requirements, we observed both planes of the plate – the lower and the upper, as well as the longitudinal section through the pin. The observations and measurements were possible thanks to the use of the Keyence VHX 6000 digital microscope and the Leica DM4 M metallographic microscope. Due to the destructive nature of the tests, the order and accuracy of individual tests was the highest priority. The research was carried out according to the plan:

1. Preparation of samples for testing the upper surface of the plate

2. Macroscopic examination and evaluation of the upper surface of the plate

3. Further preparation of the samples to enable the examination of the lower surface of the plate

4. Macroscopic examination and evaluation of the lower surface of the plate

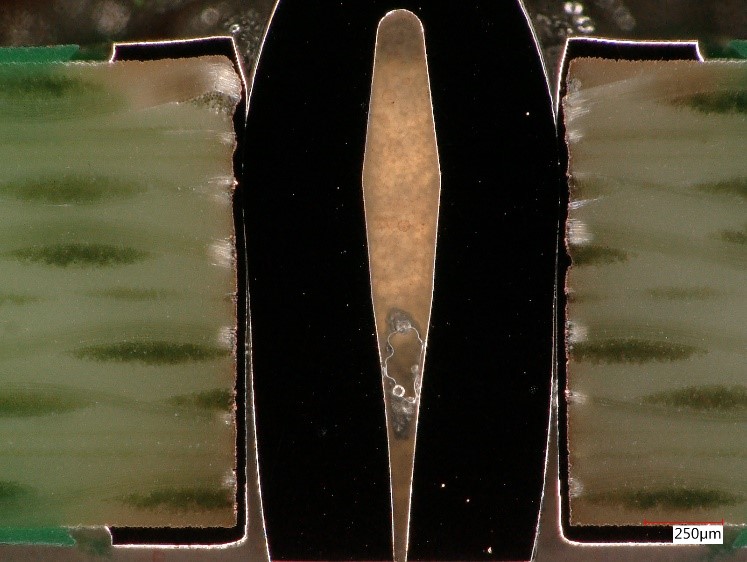

5. Performing metallographic specimens in order to observe the longitudinal section through the pin

6. Microscopic examination and evaluation of the cross-section

7. Development and analysis of research results, preparation of the report in Polish

Longitudinal section showing the metallic part