Corrosion resistance testing for the automotive and heating industries

Our laboratory performs many tests and expertise for the automotive and heating industry. One of the examples of such expertise is to determine the corrosion resistance of the tank and to check the adhesion of paint.

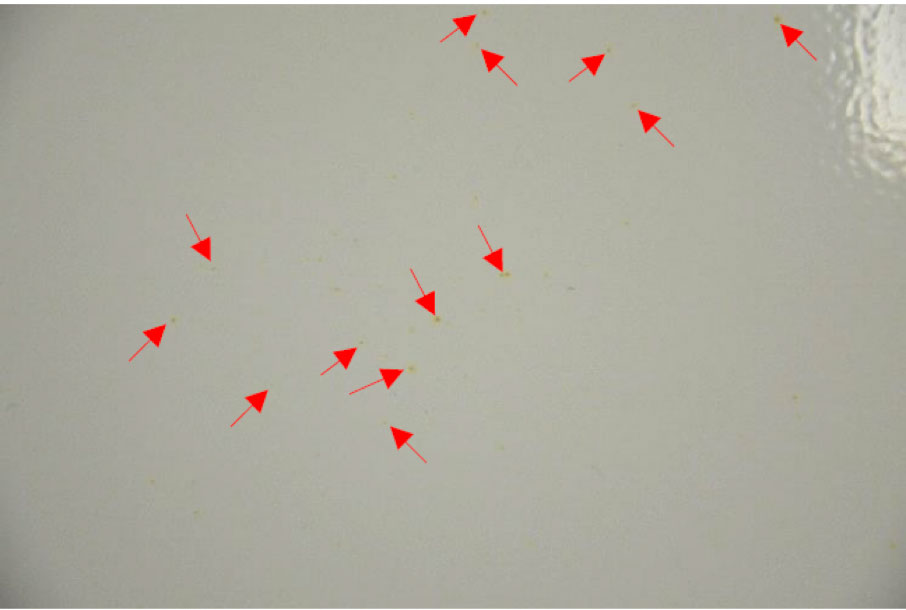

Testing of corrosion resistance can be performed by exposing the tested detail to a corrosive agent such as an aqueous solution of NaCl or steam. In this case a neutral salt spray (NSS according to PN-EN ISO 9227) has been used according to the customer’s requirements. The tanks were exposed for 240 hours, after which the degree of rusting was evaluated. The figure below shows the corrosion changes that appeared after the test.

The next test performed was the notch grid method. The test consists in making incisions with a special tool and checking the adhesion of the varnish to the substrate. The picture below shows an example of the notch grid made on the tank.

The tests carried out allowed the Customer to confirm the effectiveness of the corrosion protection of the varnish used. Microscopic tests – observations of the paint coating cross-section – may also be helpful in determining the protective properties of the paint. Such additional tests allow to comprehensively determine the changes occurring in the coating as a result of the influence of a corrosive factor. Another way of testing may also be to assess the degree of corrosion around the intentionally made scratch – the coating is damaged and the detail is exposed to the corrosive agent. In this way, it is possible to observe what will happen when the coating we want to use to protect the product is damaged.