Automotive

Find out more

Automotive

Find out more

Plastics

Plastics

Waterworks

Find out more

Waterworks

Find out more

Lighting

Find out more

Lighting

Find out more

Electronics

Find out more

Electronics

Find out more

Construction

Find out more

Construction

Find out more

Air conditioning

Find out more

Air conditioning

Find out more

Qualified team of specialists

The experience and specialist knowledge of our team allow for the professional implementation of various projects.

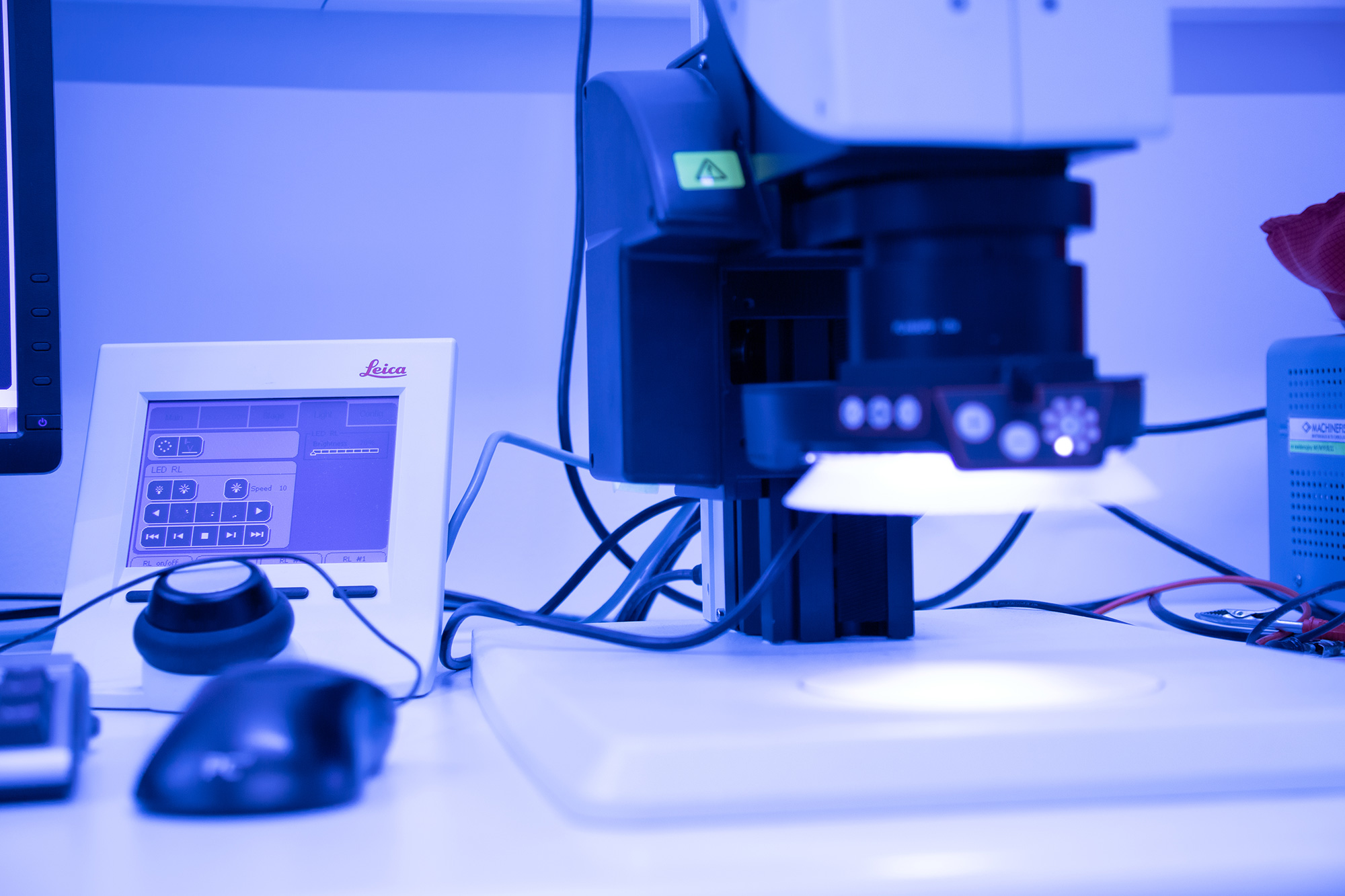

20 years of experience in conducting material research

Machinefish is reliable and impartial research of the highest quality, responding to the individual needs of the client.

Over 5,000 completed works and expert opinions

The knowledge we have is based on a strong scientific basis, many years of experience and our own know-how.

Research services

Our mission is to perform reliable and impartial research based on the knowledge and experience of our specialists. We constantly develop and modernize all processes in terms of quality to ensure the most accurate results. We treat each client individually, maintaining the highest standards.

Analiza spektralna i mikroanaliza składu chemicznego

Badania makroskopowe oraz fraktograficzne

Pomiary twardości i mikrotwardości

Badania korozyjne

Badania nieniszczące

Badania wytrzymałościowe

Material tests and technical support

We conduct research for individual clients, small and medium-sized enterprises and the largest concerns. Each order is carried out in an independent, objective, competent, confidential and adapted to the current needs of the client.

Material tests

Organization of trainings

B&R projects

Tests

Modern technology and engineering constantly strive to create new, more and more advanced solutions that meet the specific requirements of various industries. Material testing and post-failure assessments are becoming an indispensable tool in the process of design, production and operation of various products, parts of machines and devices, and construction facilities. The task of our materials laboratory located in Wrocław is to perform such analyses in a professional manner, in accordance with the most up-to-date standards and using appropriately selected methods and technologies. Find out more about our services and use them whenever necessary!

What are material tests and what do they involve?

It is a complex process of analysing the physical, chemical and mechanical properties of materials. Based on the data obtained thanks in this way, you can precisely determine how they behave under specific conditions such as load, temperature and operation. Our laboratory conducts post-failure tests and prepares assessments, which constitute the basis for precise structural identification of the material and its properties.

READ MORE

Who orders material testing?

Our services are essential in many sectors of the economy. Companies from a number of industries: aviation, automotive, construction, energy and insurance companies regularly use material tests performed by our metallographic laboratory. They do this to ensure that the structural components they use are durable, safe and meet the required quality standards. In turn, post-failure assessments reveal the causes of failures and accidents. Conclusions drawn on this basis can be used, for example, to determine the course of the failure, its causes or responsibility for its consequences.

Although our material tests are mainly associated with the design of new products, their applications are much broader. They are necessary when introducing industrial innovations, controlling the quality of manufacturing processes, during the operation of machines etc. We also provide support primarily in situations when machines or structures, e.g. bridges, pipelines or other building structures, begin to show signs of excessive wear. Then, our post-failure assessments help assess the degree of degradation of the structure and makes it easier to decide on possible repair or demolition.

Benefits resulting from material testing

Firstly, the services provided by our laboratory ensure the safe use of various types of objects, machines, vehicles and other structures. Thanks to our material tests and assessments – also post-failure ones – potential failures can be predicted and prevented. Secondly, we help optimise production costs by supporting the selection of materials with the best quality-price ratio and appropriate properties.

What are post-failure assessments and when are they performed?

These are specialised analyses carried out after a failure or accident, the aim of which is to determine the causes of the event. Based on the data obtained in an appropriate manner, it is possible to issue recommendations regarding corrective or preventive actions to prevent undesirable situations. A post-failure assessment performed by our metallographic laboratory is based on advanced material tests and examinations, computer simulations, the knowledge and experience of experts in particular fields etc.

A post-failure assessment is particularly often commissioned by companies operating in the technical and industrial sectors. In addition to manufacturing companies, insurance companies, law enforcement agencies and courts also cooperate with materials laboratories, for instance to order material tests after accidents. In turn, after a failure of a machine or production line in a plant, the management or engineers may commission a post-failure assessment to detect its causes and prevent similar events in the future.

Reliable, credible and objective material tests and post-failure assessment

In addition to safety issues, post-failure assessment and material testing, which our metallographic laboratory performs for clients from Wrocław and other cities in Poland, can also serve to save money. For example, avoiding costly breakdowns means no additional expenses resulting from unplanned repairs or downtime.

The material testing and post-failure assessment we carry out are an inherent element of modern technology and engineering. They facilitate the effective creation of safe, durable products and structures that meet specific operational requirements. Cooperation with our metallographic laboratory guarantees that all activities performed as part of material testing and post-failure assessment will be carried out professionally and in accordance with standards, and the results obtained will be reliable, objective and credible. Use our services, which we provide both as part of ongoing cooperation and as one-off orders.