Plastics research

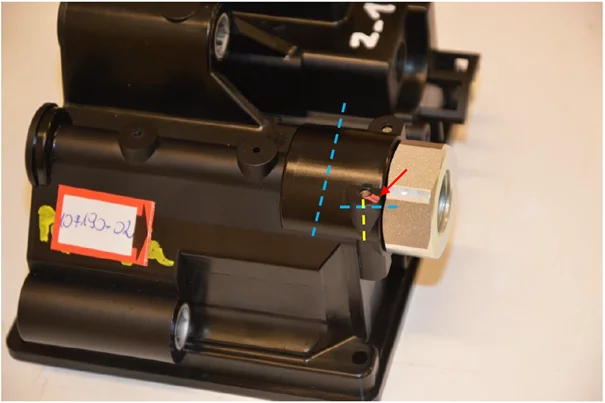

Our laboratory was faced with the challenge of solving the problem of cracking housings for applications in the automotive industry. The housings showed defects in the form of cracks in the plastic on the mounting sleeve.

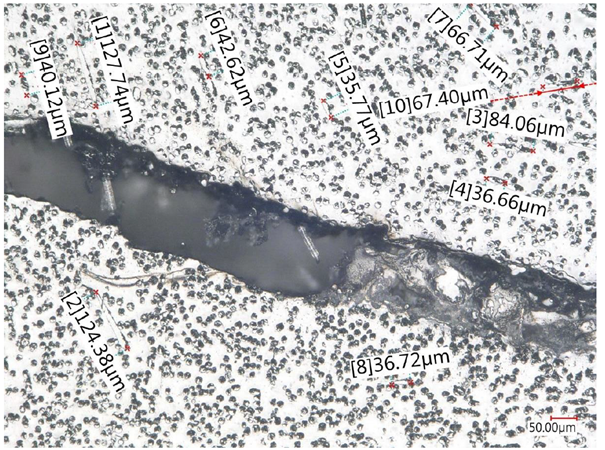

In order to identify the cause of the cracking of the casings, we performed microscopic tests to determine the distribution of glass fibers in the matrix of the material, as well as the length and thickness of these fibers. An exemplary microscopic image of the material cross-section at the fracture site along with the measurements taken is presented below:

The next step was to calculate the amount of glass fibers in the housing material. For this purpose, we used the grid method (a method based on microscopic observations).

We thoroughly analyzed the tests and found that the cause of the cracks was most likely the too directional distribution of the fibers in the crack areas. The fibers were oriented parallel to the fracture plane. Additionally, we observed that the fibers in the area of the cracks are shorter than those in the rest of the housing.

The test results and interpretations were provided to the client in the form of a legible test report. The information received gave the customer answers to his questions and allowed for a more detailed analysis of the production problem.