Comprehensive material tests in forecasting service life

One of the areas of our activity is to support individual and industrial entities in the selection of materials for specific technical applications.

Often, manufacturers, constructors consider the choice of material, its replacement with a replacement or a completely new grade of steel, cast iron, metal / non-ferrous alloy in the context of meeting the requirements related to performance.

An exemplary research path of a client who entrusted us with one of the parts installed in his vehicle was as follows:

- Preparation of samples (the possibility of cutting them out of geometrically non-standard elements using a modern EDM machine and their processing in a professionally equipped machine base).

- Analysis of the chemical composition of the material.

- Hardness measurement.

- Observation of the microstructure.

- Static tensile test (Rm, Rp0.2, Re, A, Z).

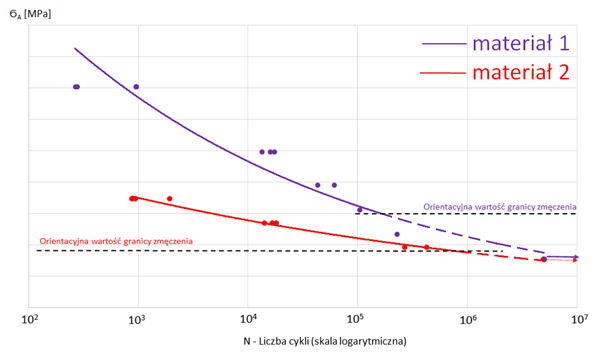

- Fatigue test on a dynamic testing machine (one of the tests lasted continuously for nearly 50 hours).

- Interpretation of results and analyzes, inference, comparing dissimilar materials and indicating directions for further research.

In this case, Wöhler curves were plotted and the strength and fatigue life of samples made in accordance with the standard from ready-made parts delivered by the customer were estimated. As a result, the customer gained knowledge of how many millions of cycles the part used in his vehicle can work without failure.

Research your part with us, do not wait for reality to verify it.